1. 품명

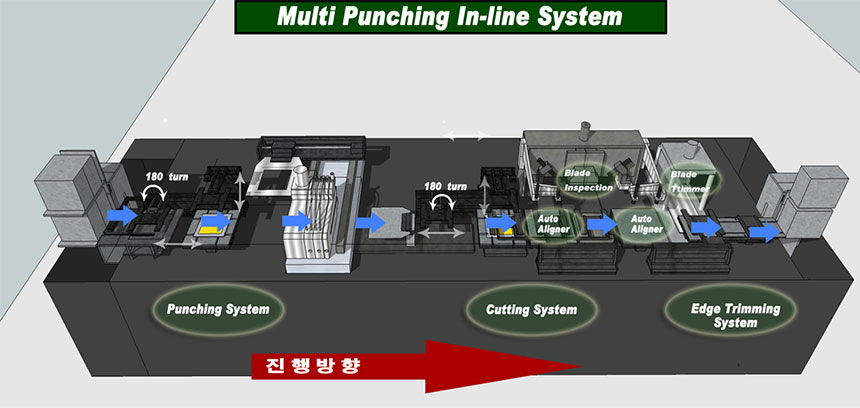

MULTI PUNCHING INLINE SYSTEM

MODEL No. AMX-325 INLINE

2. 용도

베이스 필름에 증착된 형광체 시트를 원하는 모양의 패턴대로 형상 타공을 하고 각 라인별 로 컷팅을 실시한후 외곽 트리밍을 일체형으로 가공하는 장비이다. 펀치와 다이라는 치구를 이용하여 캐드 데이터로 설정된 원형이나 사각형의 모양으로 타공하여 펀칭하는 장비이다. 또한, 많은 홀의 수를 가지고 있을때 싱글로 때리는 시간을 줄이기 위하여 GRID TOOL을 이용하여 멀티 금형을 장착하여 한번에 많은 홀을 일괄 타공할수 있는 양산 라인에 적합한 컨셉을 가지고 있다. 컷팅은 시트 크기에 영향을 덜 받도록 오토얼라인을 실시한후 X,Y 축 컷팅이 연속으로 이루어지며 하프 컷팅된 형광체 필름은 프리밍 공정으로 넘어간후 금형으로 일정한 사이즈의 내부를 한번에 따내는 컨셉을 가지고 있다. 양산에 적합한 자동 LOADER / UNLOADER 구조를 가지고 있으며 듀얼 매거진 구조를 가짐으로써 공정 일원화에도 적합한 컨셉을 지니고 있다.

3. 특징

- a. PUNCHING UNIT는 SINGLE UNIT 와 GRID TOOL UNIT 을 복합적으로 사용할수있다.

- b. PUNCH 와 DIE 교환이 쉽고 간편하다.

- c. DIE 만 미세조정이 가능하다.

- d. 금형의 교체는 상/하부 그리드 장착형이며 조립식의 구조를 가지고 있다.

- e. 펀치 칩 잔재 진공이 별도 라인으로 각 5개의 관을 통해 배출된다.

- f. AUTO CAD FILE을 별도의 CAM 변환없이 장비에 사용할수있다.

- g. PROGRAM 운용을 쉽게할수있다.

- h. 싱글과 멀티의 복합 구조로써 싱글 펀칭만 별도로 실시할수 있다. 개발 샘플 필요시는 싱글 펀칭만 사용하고 ( 단, 싱글은 4개의 핀만 사용가능 ) 양산적용시는 멀티 유닛과 혼용으로 사용하여 생산량 증대에 큰 효과가 있다.

- i. 자동 컷팅기는 오토얼라인을 실시한후 컷팅이 이루어지므로 시트 사이즈에 따른 에러를 줄일수 있다

- j. 엣지 트리밍은 원하는 모양을 금형을 장착한후 시트 내부의 임의의 사각형만 따내고 외부 더미 필름은 배출된다.

- k. 듀얼 매거진을 장착하여 작업 공정의 일원화

로더쪽의 듀얼 매거진과 언로더쪽의 듀얼 매거진을 사용함으로써 공정 일원화에 있어서통일된 매거진을 사용함으로써 후공정 이동에 편리함이 있다.

4. General specification of AMX - 325 INLINE

⑴ PUNCHING SYSTEM

-

- a. DIMENSION OF SHEET

- Standard. 200 X 200 mm

-

- b. PUNCHABLE AREA FOR GUIDE

- 120 X 120 mm (SAMSUNG STANDARD)

(130x130mm 확장성 고려)

-

- c. 형광체 SHEET THICKNESS

- 0.05 ~ 0.15mm

-

- 베이스 필름 두께

- 0.05 ~ 0.15

-

- d. HOLE SIZE FOR SINGLE AXIS

- 0.1 ~ 3.0mm

-

- e. HOLE SIZE FOR VIAS

- 0.2 ~ 0.5mm

-

- f. PUNCHING POSITION ACCURACY

- +/- 0.01mm

-

- g. IMAGE PROCESSING ACCURACY

- +/- 0.01mm ( hole-image pixel 기준)

-

- h. PUNCHING SPEED FOR SINGLE UNIT

- max. 7hit / second

-

- ( DISTANCE HOLE TO HOLE 1.0mm기준 )

- Standard 3~5 hit / second (Quality)

-

- i. PUNCHING SPEED FOR GRID MULTI UNIT

- 27 hits / second ( max. nc 기준 적용)

- Standard 18~27 hit / second (Quality)

- ( Grid pin array 9개 적용 기준임! )

- ※ (STANDARD 1SHEET 당/ 1분 30초 이내 )

-

- j. PUNCHING UNIT LAY OUT

- 1. CCD-CAMERA UNIT - 1SET

- 2. GUIDE-VIA HOLE DUAL UNIT - 1SET

- 3. GUIDE-VIA HOLE SINGLE UNIT-1SET

- 3. GRID MULTI UNIT - 1SET

- 4. GRID TOOL 금형 - 1SET 적용(9PIN기준)

-

- k. 설비 높이 ( 매거진 투입구및 배출구 높이 )

- 900mm

-

- l. 워크플레이트 히팅 기능

- max. 50" , 사용여부 선택 가능

-

- m. LOADER 쪽에 듀얼 매거진을 사용하여 개별 시트 공급 및 수납 기능 : 손잡이 접이형

-

- n. Loading시 필름 양방향 선택하여 진행 가능

-

- o. LOADER

- DUAL CASSETTE MAGAZINE TYPE

( SHEET 10장 수납 가능 / 듀얼 20장 수납 )

-

- o-1. 입구측

- 바코드 리더 장착(cognex. DMR-100S)

-

- p. AUTO CAD 에서 작업한 파일을 강력한 CAD/CAM 기능을 가진 프로그램에 의해 자동으로 변환되어 장비에 적용된다.

-

- q. PROCESS 제어및 모니터를 위한 HMI 기능이 있다.

-

- r. CONTROL SYSTEM

- *INTEL DUAL CORE 2.5 GHZ이상

- *2 Gb Memory

- *HDD 200Gb

- *52x CD-RW

- *USB MEMORY STICK 2GB

-

- s. DISPLAY SYSTEM

- 17" TOUCH LCD MONITOR

-

- t. DATA TRANSFER

- 자체 AUTOCAD PROGRAM 내장

-

- u. Program

- *AUTOMAX-GRID PUNCHING PROGRAM

- *Windows XP OS

- * AUTOCAD 2002 LT

-

- v. Motors / Drivers

- *Yaskawa(mitsubishi)AC SERVO System 400W

- *Yaskawa(mitsubishi) AC SERVO System 200W (z축)

-

- v-1. X-Y Ball screw : isoku ( japan )

-

- w. POWER SOURCE

- 220VAC / 25A

-

- x. VACCUUM

- SELF SUPPLY

-

- y. AIR REQUIRED

- 5.5~6.5KG/SQ.CM

-

- z. 이오나이저

- 바타입 제전기 장착

☞ 주의사항

펀칭기는 외부 충격에 예민한 장비이므로 장비 사용 또는 보관중 부주의로 인하여 충격이나 이물질 등의 유입으로 변형이 발생한 경우 정밀도를 보증할수 없으므로주의하시기 바랍니다.

Note :

위의 사양은 주문에 따라 변경될 수 있습니다.

위의 사양은 제품의 품질 향상을 위하여 예고없이 변경될 수 있습니다.

4. General specification of AMX - 325 INLINE

⑵ CUTTING SYSTEM

-

- a. DIMENSION OF SHEET

- Standard. 200 X 200 mm

-

- b. PUNCHABLE AREA FOR GUIDE

- 120 X 120 mm (SAMSUNG STANDARD)

-

- c. STANDARD CUTTER WIDTH

- W. 125mm ( 135mm 확장성 고려 )

-

- d. STANDARD CUTTER SPEC

- 22.4 X0.4 X0.1 TUNGSTEN BLADE

-

- d-1. 입구측

- 바코드 리더 장착 (Cognex . DMR-100S )

-

- e. AUTO-ALIGN ( 시트 PRE-ALIGN )

- 2.0 SQUARE 2 POINT 인식

-

- f. CUTTING POSITION ACCURACY

- +/- 0.01mm

-

- g. IMAGE PROCESSING ACCURACY

- +/- 0.01mm ( hole-image pixel 기준)

-

- h. PUNCHING SPEED FOR SINGLE UNIT

- max. image checking 60cut / min

-

- max. nc speed 120 cut / min

- ※ (STANDARD 1SHEET 당/ 1분 30초 이내 )

-

- i. WORK PLATE PRE-HEATER

- 300w x 2 pcs

-

- j. CUTTING CAMERA

- 46~60° posture 30X 2 units

- manual stage x,y,z 구성

-

- k. CUTTING MODE

- VISION MODE / SAMPLING MODE 제공

-

- l. BLADE EDGE 마모도 검사기능

- VISION 으로 블레이드날 마모도를 검사하여

깨진 부분을 채크해 주는 기능

-

- BLADE CLEANING 기능

- VISION 검사전에 칼날 형광체 찌꺼기 제거 기능

-

- m. Y축 이동 서보 모타

- YASKAWA(MITSUBISHI)

AC SERVO MOTOR 750W 이상

-

- n. Z 축 이동 서보 모타

- YASKAWA(MITSUBISHI)

AC SERVO 750W 이상

-

- o. CONTROL SYSTEM

- INTEL DUAL CORE PC SYSTEM

17" LCD TOUCH MONITOR

-

- p. POWER SOURCE

- 220VAC / 25A

-

- q. VACCUUM

- SELF SUPPLY

-

- r. AIR REQUIRED

- 5.5~6.5KG/SQ.CM

-

- s. 컷팅 누적 카운트 기능

-

- t. 수동 절단 모드 제공

-

- u. 이오나이저

- 바타입 제전기 장착

( Aero-Body Ion Bar. SIB3-250RD )

Note :

위의 사양은 주문에 따라 변경될 수 있습니다.

위의 사양은 제품의 품질 향상을 위하여 예고없이 변경될 수 있습니다.

4. General specification of AMX - 325 INLINE

⑶ EDGE TRIMMING SYSTEM

-

- a. DIMENSION OF SHEET

- Standard. 200 X 200 mm

-

- b. TRIMMING AREA FOR WORK SIZE

- 110 X 155 mm ( SAMSUNG STANDARD)

120X165 최대 확장성 고려

-

- c. STANDARD MOLD SIZE

- 110 X 155mm (초기 입고시 기준 )

-

- c-1. 입구측

- 바코드 리더 장착 (Cognex , DMR-100S )

-

- d. AUTO-ALIGN ( 시트 PRE-ALIGN )

- 2.0 SQUARE 2 POINT 인식

X,Y,Q 3축 구성

-

- e. MOLD POSITION ACCURACY

- +/- 0.5mm ( 비아홀 대비 따내는 더미 공간 기준)

필름 센터 기준 편측 +/-0.25mm

-

- f. TRIM SPEED

- ※ STANDARD 1 trim / min

-

- g. CASSETTE UNLOADER

- DUAL CASSETTE MAGAZINE TYPE

( DUAL 20 SHEET )

-

- g-1. 출구 매거진측

- 바코드 리더 장착

-

- g. "Z"축 칼금형 절단 방법

- MITSUBISHI AC SERVO MOTOR 750W 이상

-

- h. TRIMMING SPEED

- 깊이 콘트롤 방식 (바닥면 기준)

-

- i. 안전 장치

- 에어리어 센서

-

- j. CONTROL SYSTEM

- INTEL DUAL CORE PC SYSTEM

17" LCD TOUCH MONITOR

-

- k. POWER SOURCE

- 220VAC / 25A

-

- l. VACCUUM

- SELF SUPPLY

-

- m. AIR REQUIRED

- 5.5~6.5KG/SQ.CM

-

- n. 트림 누적 카운트 기능

-

- o. 수동 절단 모드 제공

-

- u. 이오나이저

- 바타입 제전기 장착

( Aero-Body Ion Bar. SIB3-250RD )

Note :

위의 사양은 주문에 따라 변경될 수 있습니다.

위의 사양은 제품의 품질 향상을 위하여 예고없이 변경될 수 있습니다.

- ※ 환경안전 CE 인증 취득 예정 ( 중국 천진 입고 대비 )

- ※ 325 INLINE 에서 펀칭, 컷팅, 트림 각 3가지 개별공정은 MES SOFT 를 제공하며 MES는 개별 공정 장비별 관리 시스템으로 한다.